Summer Maintenance Guide for Mechanical Equipment

Ensuring proper maintenance and upkeep of mechanical equipment, particularly during the high-temperature summer season, can reduce maintenance costs and other unexpected expenses throughout the equipment's lifecycle, lower operational costs, extend service life, and thereby enhance corporate efficiency.

The Importance of Mechanical Equipment Maintenance and Upkeep

To a certain extent, the importance of mechanical equipment management and maintenance lies primarily in economic terms. Generally, the maintenance and repair techniques for mechanical equipment are relatively simple and require minimal financial investment. To ensure the normal operation of mechanical equipment and extend its service life, it is essential to minimize damage to equipment components. In summary, this requires strengthening maintenance and repair efforts. Additionally, such efforts not only significantly reduce unnecessary cost increases but also greatly enhance the economic benefits generated by construction companies.

Generally speaking, the shorter the operational lifespan of mechanical equipment, the higher its operational reliability. The operational lifespan of mechanical equipment is inversely proportional to its reliability. Typically, a decline in mechanical equipment reliability indicates a higher likelihood of issues arising, particularly for certain types of equipment where severe damage can result in higher maintenance and repair costs. As capital-intensive equipment, mechanical equipment has very high investment and usage costs. Therefore, to better realize the economic benefits of mechanical equipment, it is essential to strengthen its management and maintenance and repair work.

Summer maintenance measures for mechanical equipment

01 On-site Emergency Response to High-Temperature Faults

“Boiling over” is one of the most common high-temperature-related faults in construction machinery. When the water temperature becomes excessively high, do not hastily open the radiator cap to release heat, as this can easily cause hot water to spray out and injure people. Instead, allow the system to cool naturally before adding water; According to operational experience and engineering machinery operating procedures, when operators detect an engine “boiling over,” they should immediately cease operations, avoid shutting off the engine, and allow it to idle while fully opening the louvers to increase airflow. This enables the water temperature to gradually decrease under the influence of the cooling fan and releases the large amount of bubbles generated by the cooling system.

02 Key Points for Routine Maintenance and Inspection of Mechanical Equipment in Summer

1. Conduct Pre-Season Maintenance and Inspection of Construction Machinery

As summer approaches, it is advisable to perform a comprehensive maintenance and inspection of construction machinery. This includes replacing the engine’s three filters and engine oil, replacing or adjusting belts, and inspecting the performance of the fan, water pump, generator, and compressor to ensure reliability. Maintenance, repairs, or replacements should be carried out as necessary. For machinery operating in high-temperature areas, appropriately increase the viscosity grade of the engine oil. Simultaneously, inspect the cooling system and fuel system for smooth operation; replace aged wires, plugs, and hoses; inspect and secure fuel lines to prevent fuel leaks; clean oil stains and dust from the engine body to ensure the engine operates efficiently with good heat dissipation.

2. Ensure proper lubrication

Equipment lubrication is one of the key measures to prevent wear and failure of equipment components.

Lubrication plays a crucial role in mechanical transmission and equipment maintenance, as it directly impacts equipment performance, precision, and lifespan. Lubrication implementation must adhere to the “Five Fixed Principles and Three-Level Filtration” guidelines: lubricate according to specified schedules, by designated personnel, using appropriate lubricants, at specified locations, and in the correct quantities. Filtration must be conducted at three stages: upon storage, during distribution, and during refueling. This reduces friction and wear, ensuring the normal operation of the equipment.

During the high-temperature summer season, lubrication intervals should be adjusted, shortening them by 0.5 to 1 times compared to spring and autumn. Monitor oil quality, as grease temperatures are prone to fluctuations. If temperatures rise, add lubricant appropriately (no more than three pumps with a grease gun). If the temperature slightly increases after refilling but then gradually decreases, it indicates effective lubrication, with insufficient oil volume causing inadequate lubrication and temperature rise. If the temperature remains unchanged or continues to rise after refilling, it indicates bearing wear, severe oil deficiency, or even dry oil inside. Therefore, for grease lubrication, adjust lubrication intervals, establish a lubrication schedule, set deadlines, and enforce them.

For liquid oils, pay attention to oil emulsification. During the high-temperature summer season, lubricating oil operates in an environment that is over 20 degrees higher than in spring, autumn, and winter. In a non-sealed environment, the oil continuously heats up and cools down. Since the oil is a hydrocarbon compound, it generates water, leading to oil emulsification. Oil emulsification significantly reduces viscosity, causing the efficiency of the original lubricating film on the lubricated parts to decrease exponentially, As a result, friction forces increase exponentially. Therefore, liquid oils also require proper lubrication planning, regular inspections, and proactive preventive measures to achieve predictive maintenance.

3. Planned Maintenance

Planned maintenance involves summarizing the wear patterns and failure patterns of equipment to develop inspection and maintenance plans aimed at preventing equipment failures and wear. Maintenance plans must be targeted, covering all parts of the equipment prone to wear and failure, with each component inspected, measured, analyzed, and summarized. Planned maintenance is the most important tool in equipment management. When used effectively, it can maintain the entire equipment system in a stable state, allowing personnel to participate in equipment operations in an orderly manner. However, if used improperly, it can lead to futile efforts, and personnel working in a chaotic environment may see reduced efficiency and diminished work enthusiasm.

4. Condition-Based Maintenance

Through various monitoring methods, equipment exhibits certain trends, such as temperature and displacement, which reflect its operational status. By collecting and analyzing these data, we can clearly determine whether the equipment is currently operating stably or is on a downward trend. Generally, equipment operating under relatively stable conditions will experience a gradual, albeit minimal, decline in performance. The key is to intervene promptly when such a decline is detected, ensuring that all components are functioning in optimal and compliant condition before proceeding with maintenance. On one hand, this reduces labor intensity; on the other hand, it not only prevents accidents but also reduces wear and tear, thereby contributing to the company's economic benefits.

In summary, for the summer maintenance and inspection of mechanical equipment, regular inspections should be conducted at designated times, and issues should be addressed promptly to ensure the equipment operates normally while minimizing wear and tear.

Breaking News: 3000kW High-Voltage Resistive-Capacitive Load

Breaking News: 3000kW High-Voltage Resistive-Capacitive Load

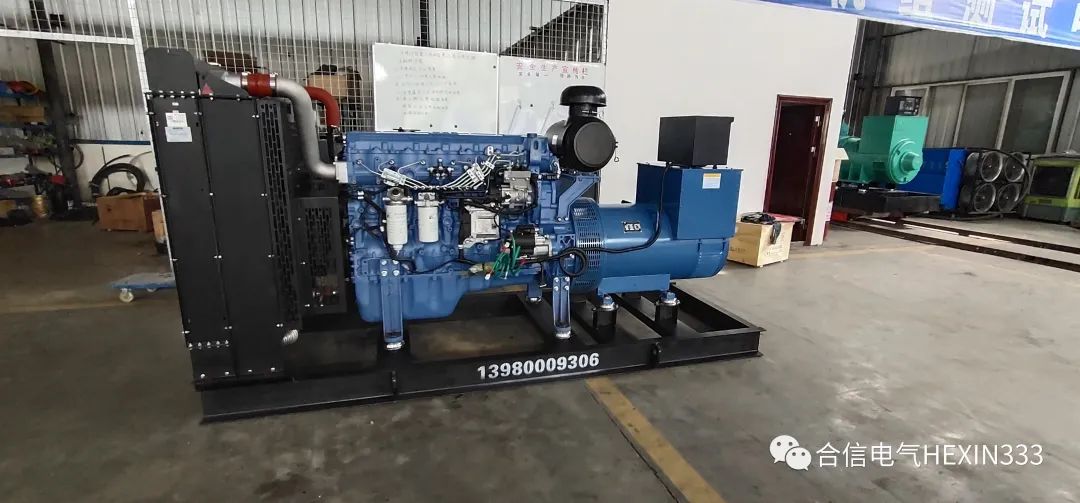

Sichuan Hexin Diesel Generator Sets Achieve Breakthrough in

Sichuan Hexin Diesel Generator Sets Achieve Breakthrough in

Sichuan Hexin diesel generator sets successfully enter the V

Sichuan Hexin diesel generator sets successfully enter the V